Do you want to increase your sales? Consider any low-hanging fruit you might have overlooked. The term “low-hanging fruit” describes those easy sales, like picking the fruit hanging on the low, easily reached branches of a fruit tree. Once you spot these opportunities, grab them! They might be more plentiful than you think.

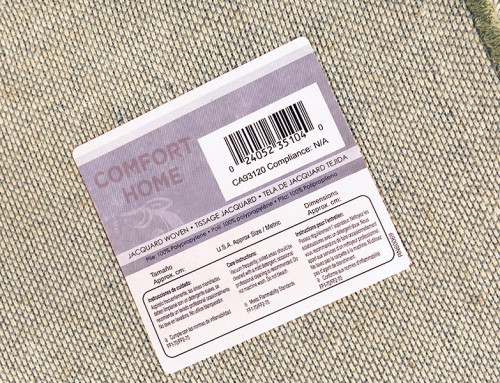

One promising area of low-hanging fruit is the addition of barcodes to both forms and labels. Small business owners, in particular, are frequently too busy with daily operations to recognize minor inefficiencies that barcoding can resolve. Integrating barcodes into forms and labels is a simple fix that can add significant value.

For instance, one end user—a tire manufacturer—faced ongoing difficulties in tracking and managing quality issues throughout its production line. While the company had a quality assurance system in place, it struggled to accurately identify when and where quality problems arose. This lack of clarity led to increased complaints from its customers, and overall product quality took a hit.

A Simple Solution for Quality Control

To address this challenge, the tire manufacturer collaborated with a Wise distributor partner, who conducted a thorough analysis of the production and distribution process. Working with Wise, the distributor pinpointed a critical flaw in the quality form that accompanied each order. It did not indicate the shift during which quality issues occurred.

Wise proposed a straightforward solution: Utilize the customer’s existing barcode scanners and incorporate a barcode to be scanned by operators at key stages—when receiving a job, during the execution, and upon completion in a specific department. This would provide accurate timestamps for each quality check, significantly improving the ability to track when issues arose in the production process.

The manufacturer loved the idea, and the results were impressive. By implementing barcodes, the company could accurately trace the specific shift and operator responsible for defects. This increased clarity allowed for targeted employee training and the documentation of improved processes for all team members involved.

Advantages for Everyone!

The results were remarkable. The manufacturer experienced a significant decline in defects, achieving an overall reduction of more than 10%. This not only addressed immediate quality challenges but also established the company as a more dependable and quality-driven supplier.

The distributor reaped rewards as well, securing orders across over 60 distribution centers. Its ability to make a substantial impact on quality control played a crucial role in gaining the customer’s trust, paving the way for a long-lasting and profitable partnership.

Where might you find low-hanging fruit? Are there customers with challenges that could be easily resolved with the addition of barcodes? With our new HP Digital Label Press, you can capitalize on those opportunities even in short runs!

Contact your Wise RSM and let us help you initiate those discussions and win new business!

Newsletter Opt-In

Every two weeks, we will provide you with what we hope is valuable content that will help you run your business and make more profit. In our newsletter, you will receive product updates, educational blog alerts, and company news. You can unsubscribe at any time.